The contribution of 3D printing to develop cancer drugs

12 May 2020 | Written by La redazione

An ENEA project aims to create the basis for personalized anti-cancer therapies thanks to 3D printing

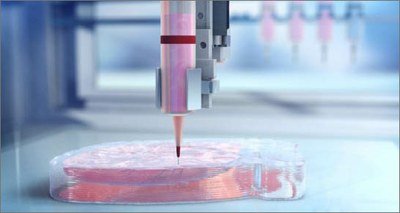

Reduced costs and times to produce more effective and personalized anticancer drugs, thanks to an innovative methodology that 3D prints a micro-tumor inside a highly engineered chip through which you can then test different drugs. This is the goal of the 3DKarkynos project conducted by ENEA together with the Florentine company Kentstrapper, specialized in the production of 3D printers.

The project involves the creation of a miniature copy of the patient’s tumor by 3D printing of organic material then grown on a special chip that will allow you to test new drugs if you test them on the patient himself but without any risk and allowing in this way of changing the care for each person. The innovative project was selected among the 21 initiatives eligible for funding available on the “Proof of Concept” 2020, the internal investment fund of 2.5 million euros created by ENEA to carry out development projects capable of demonstrating feasibility of innovative technologies and favor their technological transfer to industry.

A great help for humans and a reduction in animal experimentation. “This methodology will allow pharmacological screening on a biological model closer to the reality of any other in vitro model available to date – underlined Francesca Antonelli of the Laboratory of Biomedical Technologies of ENEA – and to reduce, not only the time and costs of the experimentation, but also the use of animal models ”. “Today most of the research of anticancer drugs is carried out using cell cultures – not infrequently lacking in predictive value – and animal models – for which it is increasingly required to find innovative solutions aimed at reducing their use in drug testing. Furthermore, from the discovery of a new anticancer molecule to its introduction on the market, up to 15 years pass, with the expenditure of human and economic resources “.

3D tumors. The project aims to 3D print a “prototype” of glioblastoma, the most common of brain tumors, using a low-cost commercial printer suitably modified and could open new perspectives in various sectors such as tissue engineering, pharmacological controls and tumor research, with a triple innovative value. In addition to the technology for 3D bi-printer, useful for high precision biomedics, a chip will be implemented that can be used to test new drugs on aggressive brain tumors, but also another cutting-edge technique: microfluidics. In practice, the traditional heads for the extrusion of polymeric material will be replaced by microsyringes which, through special “biological inks” consisting of mixtures of cells, biocompatible polymers and biomolecules, will compose the complex three-dimensional vascularized anatomical structures, that is, tumor models. These sophisticated and tiny “on-a-chip” devices, using minimal quantities of samples, will be able to “mimic” the structures of the tumor’s blood vessels, reproducing their microcirculation, functionality and complexity.