The flesh of the future? Made by a 3D printer

19 March 2019 | Written by Adriano Fontanari

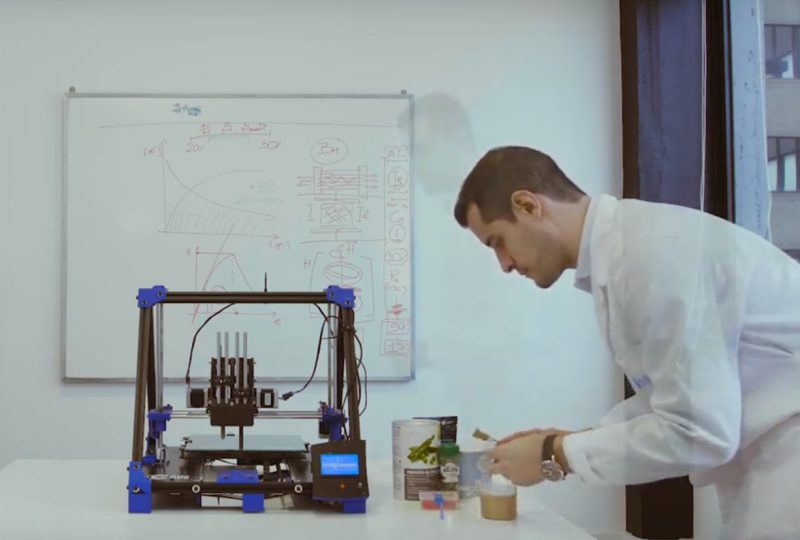

We interviewed Giuseppe Scionti, bioengineer and CEO of NovaMeat, who patented a system to produce and print 3D vegetable meat

According to the latest UN estimates, the world population in 2050 will rise to 9.7 billion people, with a consequent increase in the need for food that will be difficult to face. As for meat, for example, the current farming system will fail to meet consumer demand. Moreover, the products of animal origin are unsustainability in terms of the use of arable land, water consumption and emissions production.

To solve this problem, researchers and companies from all over the world are working on alternative solutions to “traditional” meat, experimenting with vegetable substitutes or growing them in the laboratory. The challenge, therefore, is to produce a food that has the taste, the consistency and the appearance of animal meat, despite being free of substances of animal origin.

This is what is working on Giuseppe Scionti, an Italian engineer, who with his startup NovaMeat has patented a method to print 3D vegetable meat.

Impactscool interviewed him to learn more about his invention and to understand its impact and applications.

What is your invention and how is it born?

The invention uses a tissue engineering technology (tissue engineering), in particular, the bioprinting, which I adapted to ensure that, instead of constructing a biocompatible tissue for medical-veterinary applications, it allowed me to make edible fabrics with a mechanical consistency and an appearance similar to a piece of animal flesh.

How did the idea come about?

It all started one day when I decided to biostrip an ear in 3D and I realized that it was similar in terms of consistency and appearance to a real ear, it was also composed of natural ingredients. Therefore, I decided to show it to my colleagues and they told me jokingly that it was a bit crap and that it did not look like a real ear. At that moment, I realized that what I had created could have other applications, becoming an alternative meat model.

Then I spoke with leading star chefs (Ferran Adrià and Celler de Can Roca) to evaluate ideas on how to apply this technology to build a meat substitute that had the appearance, consistency and same nutritional properties of an animal muscle, but only using natural ingredients of vegetable origin.

The creation of a bioengineered muscle in the laboratory with the ability to contract leads to greater energy consumption than is required to produce a vegetable meat substitute.

In this regard, what does the market offer today?

In the field of vegetable meat, there is the vein of burgers that have the taste of animal meat like the Impossible Burger, but do not have the same fibrous consistency.

Otherwise, the meat of The Vegetarian Butcher, has a fibrous consistency and is based on soy, with a taste similar to chicken. Our patent allows us to have the consistency, appearance and taste of animal meat at the same time.

How?

It is possible to obtain the appearance of animal flesh thanks to a technique borrowed from biomedicine, which allows precisely with a 3D printer to build tissues, biomimetics, which imitate nature.

What are the possible applications?

I see two phases of application of this technology. The first of prototyping and research will concern innovative hospitals, space agencies and restaurants. The meat will be printed using different Nespresso-type capsules (chicken, tuna cow) and a sturdy printer. In the hospital, for example, it will be possible to provide food with consistency and personalized nutritional properties, for patients and for those suffering from dysphagia (therefore with problems with swallowing).

Another use concerns space agencies. Astronauts can not only eat freeze-dried foods or liquids otherwise the muscles of mastication, which are no longer used, are reabsorbed, decreasing the volume even of the bone tissue of the jaw due to lack of chewing. This will be a problem in the near future for long journeys, where it will be necessary to provide astronauts with a varied and balanced diet. By mixing this powder with water and using a printer, it will be possible to produce personalized food.

Phase two, will cover mass production, and try to use technology as an alternative to animal meat also in supermarkets. In this phase it will not be possible to use the 3D printers currently in use (being structurally very slow) but it will be necessary to use industrial systems with large machines and containers.

What impact can this invention have?

The application of my invention is not limited to the production of a valid alternative to animal meat, but will also have multiple effects on the environment. The current farming system is unsustainable, not only for ethical-moral issues but also for the resulting greenhouse gas production like methane, that represents 15% of total emissions. The increase in population will determine a need for a protein that the farm will not be able to provide, given the lack of sufficient arable land. Currently, in fact, around 83% of all arable land concerns animal breeding. Alternative meat production could mitigate this problem, among other things free of antibiotics and hormones.

The advantage of packaging and pasteurizing the meat produced through my system will be particularly useful in support of populations living in rural or inaccessible areas of the planet, where it is difficult to transport products for long journeys.

The next goals?

We are evaluating the possibility of producing meat by incorporating useful drugs to fight endemic diseases now present for decades in specific rural areas of the planet.