Bio-composite materials for a more sustainable building

28 July 2020 | Written by Sara Falulera

The future of construction becomes more sustainable thanks to new materials that enable the development of the circular economy and processes with low environmental impact

The construction sector has intrinsically slow dynamics and is tending to be reluctant to innovate, therefore little inclined to adopt more sustainable technological solutions on a large scale and in a systemic way. Even today, most buildings use unsustainable materials and processes throughout their life cycle, from construction to disposal. Indeed, incorporated CO2 emissions are present in a large number of building materials. These are all those emissions that range from the extraction of raw materials, to the processes of product realization, up to the disposal of the same.

A report drawn up by the Global Alliance for Building and Construction confirms that the construction sector is one of the most harmful to the environment. The analysis of the study was presented at the end of 2019 at the COP25 in Madrid, the UN conference on climate change, and it emerged that the construction sector is responsible for 39% of the carbon dioxide emissions dispersed in the environment, for 36% of consumption global energy and for 50% of the extraction of raw materials. Emissions that are mainly responsible for climate change and the increase in the earth’s temperature. Furthermore, the materials used are a problem even at the end of their life, as many are classified as special and subject to a particularly long and expensive treatment to be disposed of.

In recent years, however, thanks to the research of universities and the start-up work with a high technological content, a trend change is starting due to the development of new solutions.

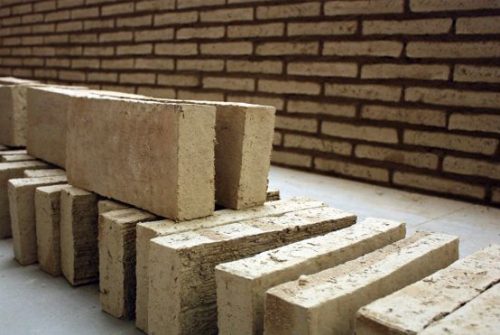

The bio-brick in hemp. ENEA (Agency for New Technologies, Energy and the Environment) and the Polytechnic of Milan within the project “Energy requalification of existing public buildings: direction Nzeb (Nearly Zero Energy Building)” have created a bio-brick made of hemp and lime capable of ensuring a low environmental impact while maintaining high performance. As part of the project conducted by ENEA, bio-brick walls were tested and created which resulted in a high energy performance for the thermal insulation of buildings. Hemp is in fact an increasingly used material in green construction, both for its characteristics of natural material, and for the wide availability on the territory as well as the low impact of its production cycle on the environment, as explained by Vincenzo Luprano, researcher of the Center ENEA searches.

For the construction of these bricks, the wood waste of industrial hemp, the canapulo is used. The mixture of lime and hemp is called lime-hepulo which, in addition to being an excellent insulator, is also a porous material that makes the building ‘breathe’ avoiding the formation of mold and other substances harmful to health; it is in fact able to maintain an internal temperature of about 26 ° C without resorting to the use of the air conditioner thus obtaining environmental benefits for the reduction of CO2 emissions due to air conditioning and significantly reducing the bill.

Bacterial bio-bricks. Hemp brick is only one of the solutions for the production of materials for a more sustainable building, the bioMASON company is developing bricks starting from bacterial crops capable of converting sand, nutrients and other raw materials into organic cement. It was the first company to use bacteria instead of heat to convert nutrients into calcium carbonate that can harden the sand and turn it into a robust building material. A process carried out entirely at room temperature, unlike traditional building materials, to produce which requires a high energy consumption process. This innovation would allow to produce an organic brick with the ability to breathe and absorb the polluting particles present in the atmosphere.

Building materials from food waste. Other solutions with a view to circular economy arise from the recovery of waste from the agri-food industry. RiceHouse has been studying products for architecture deriving from rice waste for years. At the beginning of 2020, at the “Klimahouse” fair in Bolzano, the company presented an entire line of products such as plasters, panels and mortars that guarantee energy savings and reduced environmental impact.

CALCEDICAMPO, on the other hand, is a company that reuses the waste of rice production but also deals with producing lime and sand, to be used as an aggregate, through the recovery of egg shells. The advantages are therefore multiple and range from reduced cost and low energy consumption to the property of being restorative plasters, that is, anti-mold and anti-condensation. Another advantage lies in the price, with the same incidence per square meter of common bricks they have much higher performances.

Construction offers great possibilities for change, approaching a circular economy model means innovating processes, from production to the transformation of waste, to change the way products are conceived. Today in the construction field there are more and more products made from waste material and thanks to new technologies, regulatory facilitations, the construction sector is finally moving towards a more environmentally friendly direction. The key to sustainable development, the basis of the revitalization of the building industry, lies in the materials and processes aimed at recovering waste materials. The biocomposite materials therefore combine the needs of circular economy with energy savings thanks to high performance.

Today only through the key of the circular economy it is possible to look in a new way at the relaunch of the construction sector, reducing the impact of the interventions and pushing the recycling of materials. Given the many innovations underway and the necessary and obligatory growing awareness of environmental sustainability, it is not difficult to imagine a future where construction creates value for the economy and people without wasting resources and polluting the environment.