Bioprinting: 3D printing applied to medicine

10 April 2018 | Written by Filippo Scorza

3D printing mainly uses materials of plastic, metallic and polymer origin. Thanks to Bioprinting, however, we can replace these elements with living human cells, opening the door to new interesting applications in the medical field.

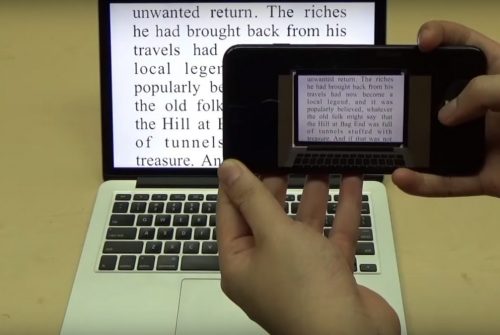

All of us have heard at least once about 3D printers, or printers that can produce and replicate physical objects using additive technology, starting from a three-dimensional model. By depositing several layers of plastic material, the 3D printer starts to work from a digital file, sequentially printing one layer after another.

The materials used to date in 3D printing are mainly made of plastic, metal and polymer, but let’s try to imagine if we could replace these elements with human living cells. Yes, exactly, use stem cells and other organic compounds to artificially reproduce tissues, blood vessels and organs. It may sound like science fiction, but this technique has already been tested and is called as Bioprinting: a new approach, which opens new doors and accelerates the current bioregeneration techniques in the medical field. The main advantage of an artificial reproduction technique of this type is the elimination of rejection factors because the new tissue or organ would be created “ad personam”, starting from the same cells of the recipient individual.

One of the current obstacles to bioprinting is the vascularization of printed tissue. We know, in fact, that it is not a problem to use stem cells to create specific tissues, but it is difficutl to develop their relative vascularization: without capillaries that carry nutrients and eliminate waste, any tissue is destined to die.

One of the bioprints that are emerging in this sector is the Organovo’s Novogen: a printer equipped with two robotically controlled nozzles, one for the storage of stem cells and one for the support material, called hydrogel. Obviously, in order to work, it needs a three-dimensional model or design of the fabric to be reproduced, just like in traditional 3D printing.

Up to now, through the Bioprinting we have managed to print modest portions of skeletal muscle, blood vessels and bones, up to the most recent print of a mini-liver about 4mm in size, able to perform the same activities as a real organ. Despite its average life time of about five days, this mini-liver is able to synthesize proteins, cholesterol and metabolize alcohol. Another area of application of Bioprinting is that related to the regeneration of portions of epidermis directly on burn wounds: the bio-printer, in this case, is equipped with a special infrared scanner able to analyze and reproduce the 3D model of the fabric damaged, which is subsequently made by the printer.

It must be said, however, that the tissues or organs reproduced through this technology have not yet reached a level of perfection that can be implanted in the human body but, taking into account the exponential growth of technologies that took place in the last twenty years, we can to hypothesize that total bio-compatibility can take place in the near future.

As often happens, technological progress, science and medicine intersect each other taking inspiration and adopting solutions from contexts that at a glance nothing would have in common: the exponential technologies are not additive but rather factorial.